Brief Synopsis

I was a participant in the F.I.R.S.T. Robotics Competition (FRC) from sophomore year of high school until graduation. I was a very active member on my high school’s team, Team 1495, for all three of those years. I still strive to help the team in their current endeavors even without being physically present during the season. During my time on the team, I personally managed over $30,000 in funds, became a club leader of the approximately 50 members after only one year, presented to 30 school board members on two separate occasions, was highlighted in district-wide STEM presentations, gave a presentation to 11 superintendents from the surrounding area, mentored our intermediate school robotics team, and led our high school robotics team on the most successful three-year spread we saw in 15 years.

In-Depth Explanation

During my sophomore year, myself and another student developed and created a device for the robot that attached to a hanging rope, lifted the 120 pound robot two feet off the ground, and hold it there. This mechanism was incredibly successful. It was the primary reason that our team won a regional competition and was able to attend the Mid-Atlantic District Championships that year, which comprise of the top 32 out of 132 FRC teams in the Mid-Atlantic region. This was the third and second time, respectively, that our team had won a regional competition and advanced to the District Championships. In fact, this device was so successful that when faced with a similar challenge during my junior year, our team decided to simply take it from the previous year’s robot and attach it to the new one.

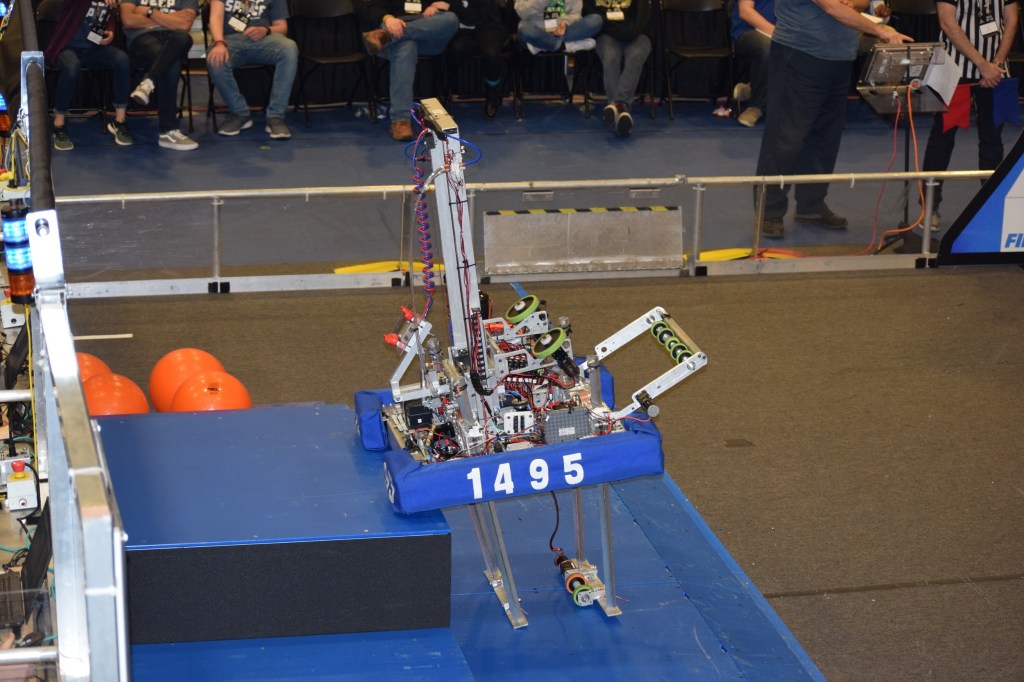

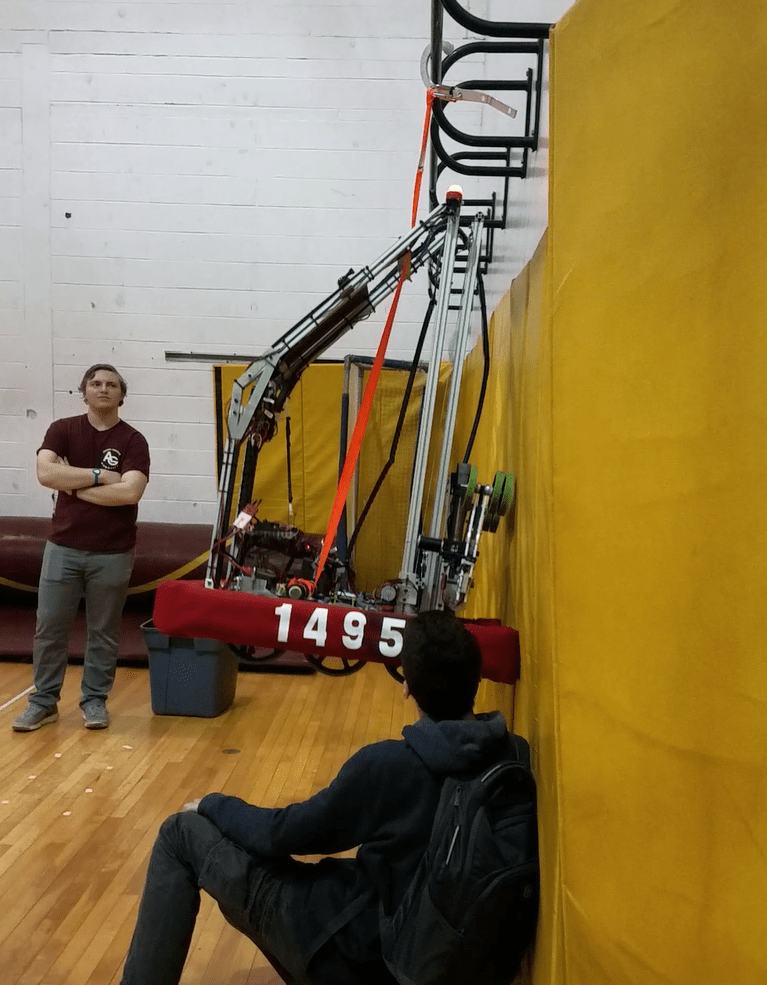

This picture shows the device in action on the robot from 2018, my junior year. This year, we had to hook a bar and do a pull-up with the robot, holding it at the top for a certain amount of time. Since the concept was so similar to the year before, we just attached the rope ourselves and used an elevator system (as seen on the right side of the robot in this perspective) in order to raise the hook up. This elevator system was a combination of a rack and pinion with a cascading series of tubes, and was another part of the robot I helped with.

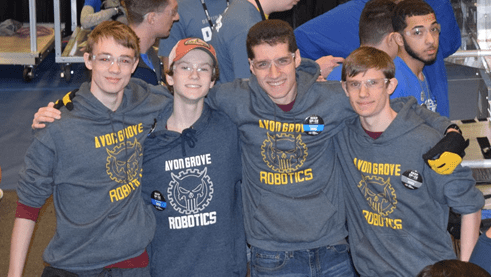

This is me sitting in front of the robot, I was making sure nothing broke during our testing since it was my mechanism that was holding it up.

During my junior year on the team, I was a cabinet member and the secondary head of our mechanical team. Even though it was only my second year, I had proven myself enough to earn those spots on the team. The robot from this year, while coming 4th and 6th at both of our regional competitions and failing to qualify for the district competition, was regarded as the best overall robot our team had created to date in our team’s 14 years of existence. I took this as an extreme motivator for next season and vowed to one-up it.

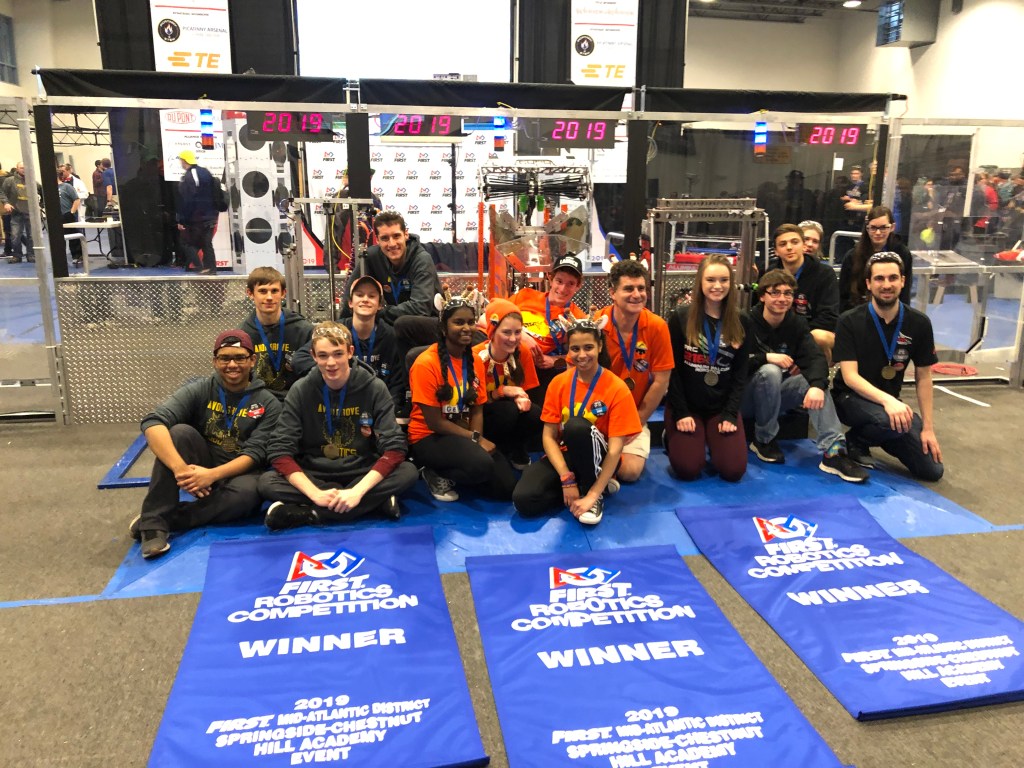

My senior year was by far the best robot our team has created. I was a cabinet member yet again, decided every mechanical decision on the robot as the mechanical lead, and was selected as the driver of the robot for our competitions, so I know it may seem I am biased. However, this was only the third year in our team’s existence that we both won a regional competition and advanced to the district championship in the same year. We also placed 39th out of 132 teams in the Mid-Atlantic, our highest ranking to date. We also ranked in the top 10 in terms of offensive and defensive capability. In general, it was the best overall robot from our team, and I am honored to have played such a pivotal role in it.

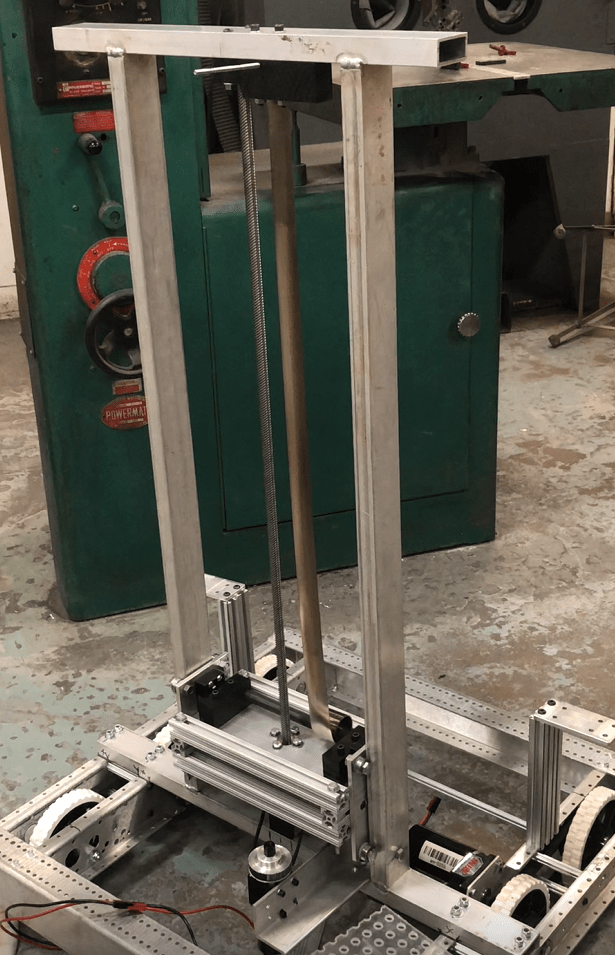

In these pictures from our senior year season, you can see a brief encapsulation of our success and of our robot. The top left picture shows the balls that we had to pick up and the roller device we created reaching out from the robot in order to collect it. In that same picture, the yellow and black panel stuck onto the wall was another object we had to manipulate, and that was done with a device on the other side of the robot. The top middle picture shows the robot climbing an 18 inch step. The rightmost image was our elevator, which one was the most designed parts of the robot behind the part that allowed us to climb the step. It was a three foot long vertical lead screw that when rotated by a motor, moved the central plate up and down. That plate was prevented form rotating by a system of bearings that ran along rectangular tubing on either side. We also implemented a constant force spring in order to alleviate any force on the lead screw and allow it to travel three feet in under a quarter of a second while still being accurate to a sixteenth of an inch. Because I was the mechanical subteam lead this year, I had a hand in the design of all these components, and was the primary designer of our elevator system and the manipulator system for the game pieces. Bottom left is our drive team along with the drive teams of our two teammates when we won the regional competition. Bottom center is a picture of us during our attendance to the district championship.

While it may seem that one person could not have the impact I am claiming to have on the success of the team, I do agree. However, in this three year span of me being on the team, myself and only one other member were the only constants outside of the teacher running the club. Hence, while our success could not have happened without every individual member each year, one cannot ignore consistencies that lead to success.

I could talk – and have talked – about any of these robots (especially the one from my senior year) for hours on end. However, the experiences I gained over the three years being on the robotics team were truly priceless.

One of the opportunities I had through the robotics program was being able to present at the Boeing facility in Philadelphia in 2017 and 2019(shown in picture), and then tour their factory floor after our presentation. This ability to present our hard work to actual engineers and hear their feedback was incredibly beneficial for my growth and our team’s growth. Being able to see the Boeing factory floor as well gave me an idea of the potential scale my designs could have in the future, and allowed me to talk to professionals in the field I was pursuing.

One of the things I did not expect to come from my time on the robotics team was the reach I would get in my school and community. Over the three year span of being on the team, we presented at two district-wide STEM nights meant to highlight STEM being conducted in the district. The second time we did this, it was my senior year, so I personally helped the head of the event in organization and execution of the night, and our team was a headline presenter for families and faculty. Also during my time on the team, I presented twice to our school board about what our team was doing and how we achieved our goals using what we were learning in the classroom through both core classes and electives. In my senior year, I was asked by our principal to give a presentation about the team and my personal experiences to 11 visiting superintendents who were learning about STEM in our high school. Shortly after the visit by these superintendents, the principal of my school again asked if I would be willing to be in a video about the team for the school board. I once again was honored by his request and accepted (The video made about the team is below this paragraph). These experiences helped me develop my professionalism and public speaking since every one of these was talking to adults whom I had to be very professional with in my presentation.

An unexpected opportunity that I had during my senior year was becoming a mentor for our intermediate school’s Lego robotics team. Getting to help these students provided me a new perspective on both my engineering on the design process in general. The youths’ approach to the challenges was unique and it showed me that all the recommendations to “think like a kid” to solve a problem have legitimate basis.

During all three years on the team, I was able to thoroughly delve into the entire design process, as we have to go through planning, prototyping, iterating, and production of our designs every single year in order to achieve different goals. Because of this, I was able to learn the ins-and-outs of properly designing for a specific task, as well as solidify my desire to pursue mechanical engineering in college. I also learned about working with other engineers in order to achieve a common goal, as I had to work with people not as mechanically inclined as myself but had more expertise in electronics or coding in order to make the best robot possible. During my time as a cabinet member, I was able to delve into the business aspect on multiple fronts: I personally handled over $30,000 over the two year span, and fundraised approximately half of that through reaching out to business for sponsorships. I was also in charge of delegating the 50 members of our team at times and trying to utilize every member where they would be most useful and would learn the most at the same time. This leadership ability was something I admit needed improvement at the time, but I feel I am consistently . I also understand how to work on a team when I am not the leader and how to listen to others ideas, as I had to many times during my years on the team. Being a member of my high school robotics team turned me into not only the engineer and student that I am today, but helped make me more well-rounded person overall. I would not be where I am without those three years of experience.