During my freshman year at the University of Pittsburgh, I joined a club focused around designing and creating a formula one style car. This club was the Formula Society of Automotive Engineers, also called FSAE. Throughout both of my first two semesters at Pitt and on the team, I helped primarily through my experience in machining, but also 3D modeling in SolidWorks.

Due to my lack of experience in vehicle-dynamics-specifics, as well as my general knowledge of vehicle specifics lacking beyond the general concepts, I wholeheartedly dedicated myself to helping the team through the machining aspect. As I had been machining for three years before joining the team, I already had a very solid base that could be built upon by the more experienced machinists. The pictures above show a brief encapsulation of what I helped with. On the left is a carbon fiber layup created for the dashboard of our car that we laser-cut holes into for buttons and a screen, I helped make the holder so it would sit flat in the laser cutter. On the right is a steering column adapter that was created entirely from scratch from just a stock piece of aluminum using a manual lathe for all the main components and a CNC mill for the part on the end that isn’t round. Because I had been 3D modeling in SolidWorks for four years before joining the team, I also assisted in the design work for the car. For all of my contributions, my skills coming into the team were greatly beneficial but were refined and altered by more experienced members of the team as the year went on.

Unfortunately, as most things were during the spring of 2020, my freshman year on the team was cut short by COVID-19 as we were all sent home from campus and the competition was cancelled.

At the end of my freshman year, in preparation for the upcoming season, I was asked by the team’s directors if I wanted to become a subteam lead for next season. This meant that I would be in charge of designing, creating, and making sure an entire subsystem of the car worked optimally. While pleasantly surprised by the level of trust that was put in me, I accepted the challenge readily, taking charge of the brakes subteam. Due to no prior experience in the classroom learning about heat and mass transfer (one of the principal properties of brakes), I spent the summer researching. Luckily, there was an amazing group of upperclassmen that supplied me with textbooks and notes on relevant information and helped clarify my inevitable questions.

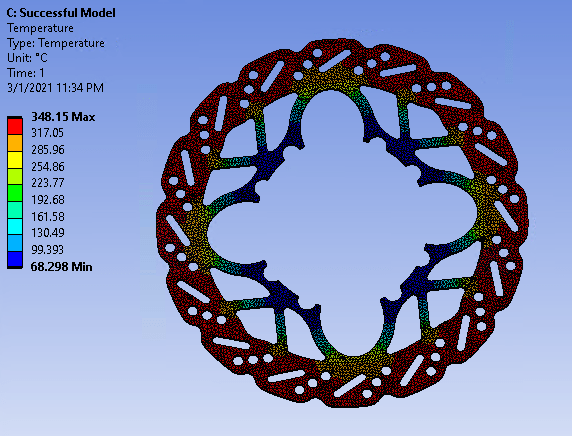

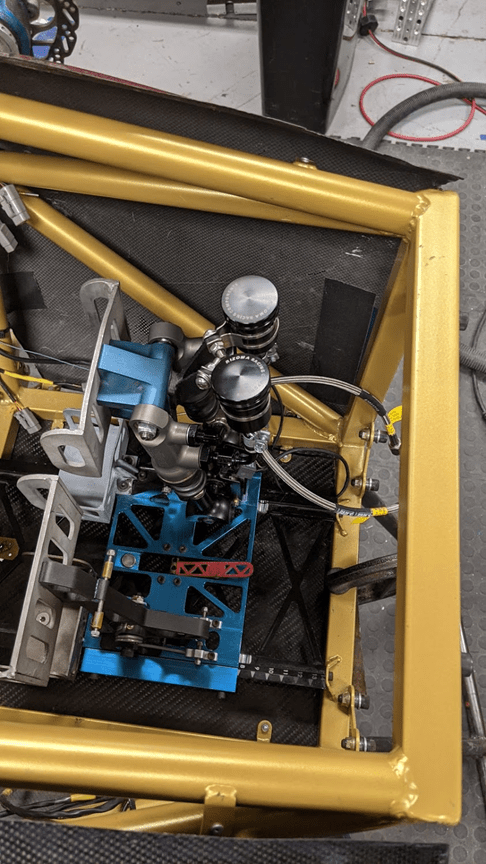

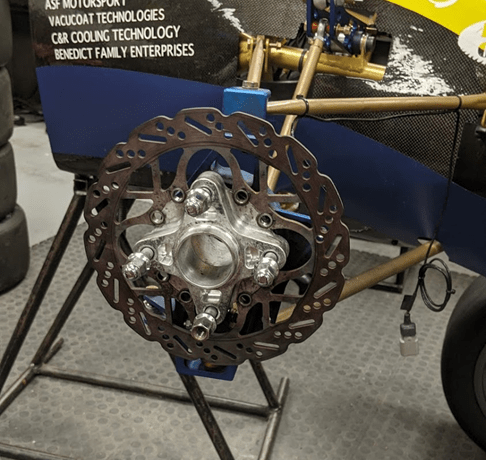

What I was able to complete during this season of being a brake subteam lead was the beginnings of a better simulation for the brake rotors. In past seasons, the ANSYS simulations did not include any convection from the air or radiation from nearby sources. Since we had determined this was a part of the design process that was weakest (and I believed I could make changes to impact it) I started on a proper simulation. An image of my improved simulation is below, as well as the actual rotors in-situ and the pedalbox that held the adjustable pedals (which also fell partly into my subsystem).

Junior year was a drastic change from the previous year, both personally and team-wide. With most of the team graduating, we were left with very few members, which meant little manpower and little knowledge. My role changed from a single subteam lead to a more general role. I began assisting multiple subteams, leading our manufacturing group, and focusing on recruitment. This approach was an immense success. At competition, we finished our endurance event (a 22 km course that only about 30% of teams finish per competition) and placed 32nd overall out of 99 teams. This was an extremely rewarding season as we brought on the newest class of team members in years and were able to perform well with people who were willing to put in work and learn. Outside of the physical competition, there was also a focus on improving the team culture during this season since COVID left it strained but we had a chance to “reset” it. This focus paid off, the culture of the team as a whole became much better than it was my first two years and became a group of people that genuinely feels like a team.

https://www.ansys.com/blog/panther-racing-leads-engineering-innovation

https://courses.ansys.com/index.php/courses/aerodynamics-of-an-fsae-car-2