During my high school years, I was able to create multiple different projects in between my time with clubs, sports and homework. These projects all taught me a wide variety of lessons regarding the design process and specifics about creating for both a creative and a functional purpose.

During my senior year, while I was a Teacher’s Assistant in my school’s wood shop, my shop teacher was asked by the administration to create a sign for the upcoming TEDx event being held at the school. Since I was one of the most experienced in the shop at the time and because I had the time, my teacher enlisted my help in creating these signs.

We had only a week to complete all the signs, but we successfully fabricated and painted all the signs in time for the event. These signs will be used for every TEDx event at the school for years to come, and we designed them to hold up for that timeframe.

One of the important things that I learned during this project that I previously had very little experience with was how specific a company’s requirements can be at times, and seemingly for the simplest things. For example, since the event was an official TEDx sponsored event, we had to ensure that every little detail followed their strict rules. The fonts had to be exact. The sizing of the logo compared to the school name had to be a certain ratio. Both red and white used for the letters had to be an exact color. This taught me that in the future, even though my project might be on a strict schedule, I needed to make sure it followed all rules outlined by the client.

Another project I was happily roped into during my senior year as part of my time as a Teacher’s Assistant was this lifeguard chair shown here. The reason why we made this was because the PTA wanted it for After-Prom (due to their theme of choice). Because of when they asked us, once we decided on a design, myself and my wood shop teacher had only 3 days to construct and paint it. The design we found that we believed would work originally had the height of the seat being 6 feet off the ground. We wanted to make it more interesting than a measly 6 feet, so we raised the height all the way to 11 feet. The issues we did not initially consider were how to get up to a seat 11 feet in the air since the design did not anticipate that alteration, as well as the extreme instability that now arose from it being so high. So, once we constructed the lifeguard stand, we added two of our own custom-made steps/seats, and increased the overall stability of the chair in all directions with rails and angled pieces.

We did successfully complete the lifeguard stand in just 2 days of work, which gave us an entire day to paint, leading to us delivering it right on time. In the end, we were able to fit 10 students on the stand comfortably with our additional seats/steps and with no risk of it tipping due to the extra stabilizing parts.

What this project taught me is that when you alter a design, there can be unexpected consequences depending on how drastic the changes, and you will need to adapt to them in order to make the design work. What we did not realize would happen was the instability and the inability to reach the actual seat once we decided to raise it up by five feet. This was something I had experienced through my time on my high school’s robotics team as well, but this was much more unexpected.

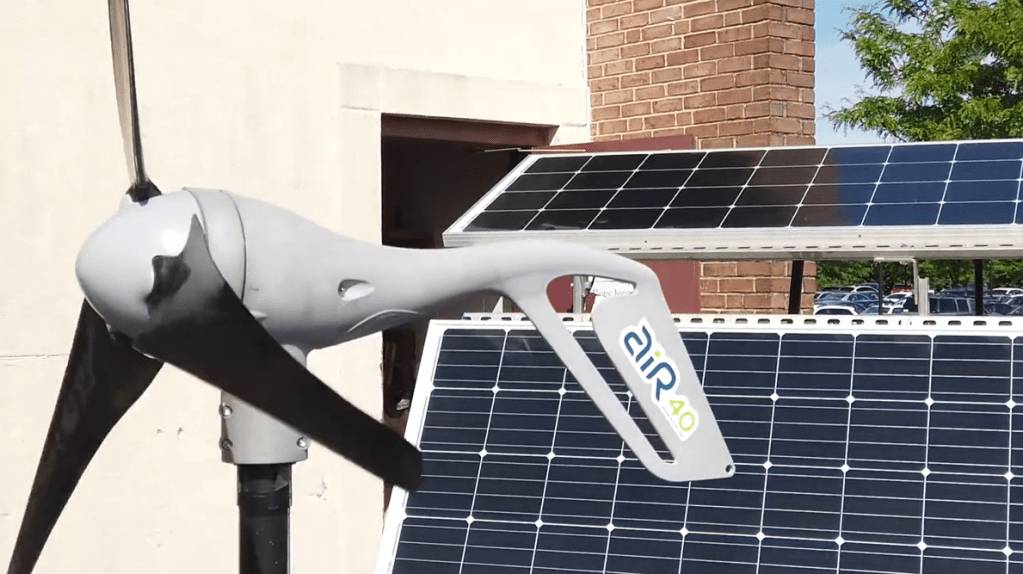

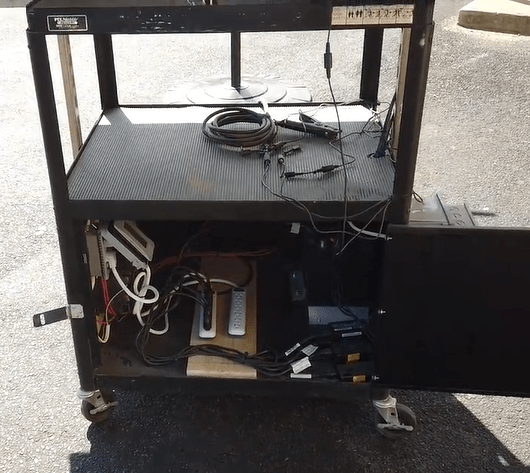

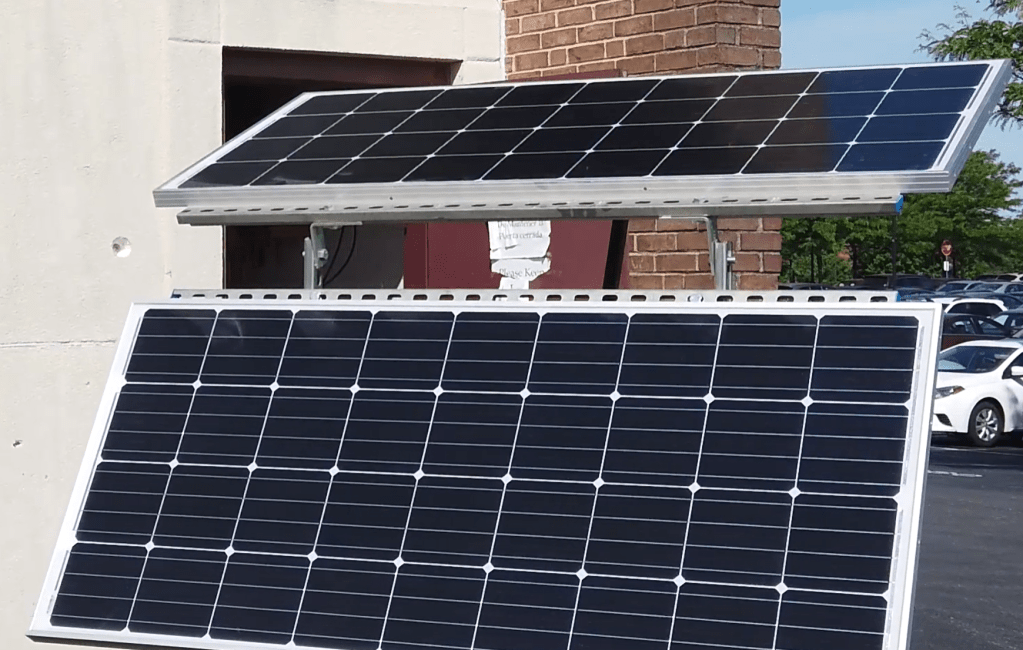

Yet another project that I helped with during my senior year was part of a district-wide green-initiative. I assisted in the creation of a wind turbine and portable solar-cart that the school could use for renewable energy sources. The only parts that we purchased for these projects were the physical turbine, the solar panels, and the primary converter to take the solar power into usable AC power. We were able to mount the wind turbine on the stand of an old fan we found. This allowed us to make adjustments to it and test our electronics. Later plans were to mount it on a permanent pole on the roof of the high school, but that did not happen while I was there. With the solar cart, as seen in the second picture, we used an old rolling TV cart in order to both house all the electronics, mount the solar panels, and have a place to rest devices once plugged into the system. We designed it so both panels can be turned to face the sun (as shown in the third and fourth pictures) but if the cart needs to be moved, the top panel can be folded down and it can be wheeled through a standard door. These projects were incredibly interesting to work on and the first renewable energy projects I worked on.

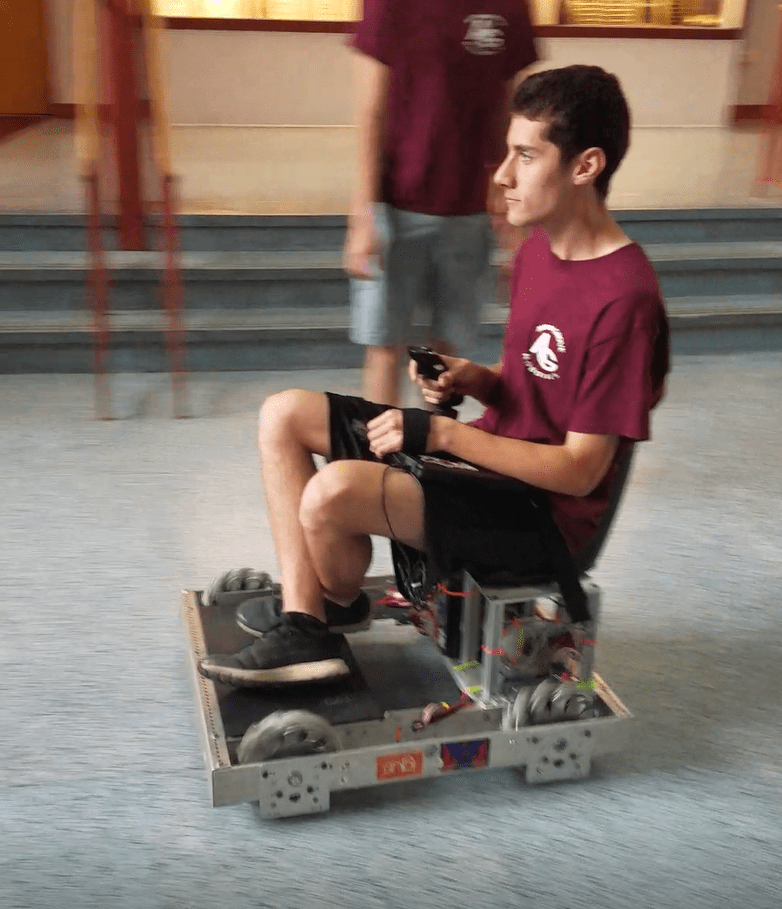

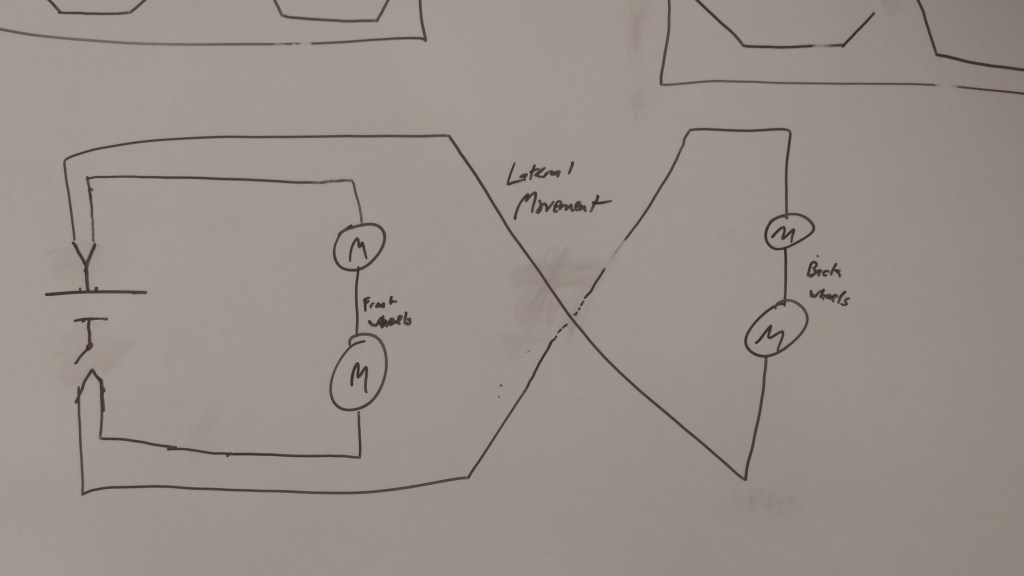

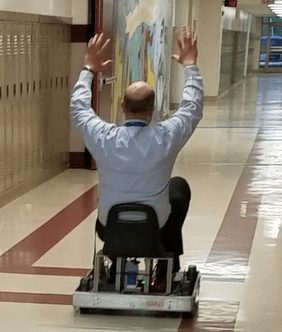

While all the projects on this page would make it seem like I only did extra projects my senior year, perhaps my proudest project was my sophomore year. It was my first year on my high school robotics team, and we had just finished up our season. Our team was asked to give a presentation to the school board about our club and the robot we had made for our season. Myself and another student wanted to create something else to present in order to show off to the school board, as well as prove our abilities. What we came up with was to take the basic chassis of one of our past robots and turn it into a go-kart. By the time we were informed that we were going to give the presentation to the school board, we had three days to prepare. Once we realized what we wanted to create, it left us only two days to go through the entire design process. As evident by me talking about it here, we were in fact able to retrofit one of the robot chassis so it was able to hold a person. It was incredibly fun to make, and over the following two years of being on the team it was a wonderful publicity piece. The picture on the far left is me right before our presentation to the school board during my sophomore year. The middle picture is one of our schematics during our planning phase when we were trying to figure out how to make the chassis able to drive the weight of a person. The far right picture was during my junior year and is of me driving around the intermediate school principal during an event our club was presenting at.

This go-kart showed me early on that I could make projects fun by taking something from its standard purpose and adapting it. By working 1-on-1 with a more experienced member of the team on this project, I learned a lot about robotics and the design process in general, which helped drastically cut down on my learning curve and allowed me to go deeper into robotics and engineering in future years.

While these extra projects may not have impacted my GPA, may not have been a direct reason I did better in classes, or had any other benefit scholastically, the opportunity to take a couple days to use what I learned in my classes and clubs in order to create something useful/fun was beneficial in other ways. These projects helped me develop a deeper understanding of the design process, especially under a time restriction. I was able to learn about a variety of different materials – both natural and unnatural – and benefits of each. I was able to hone my hands-on ability in both physical construction and during the planning process. They were not only fun to go through, but helped me learn in a unique way as well.